The structure of the press

A press usually refers to a press that is driven and controlled by a motor. It realizes the movement process of the slider by driving the eccentric gear by a motor. Through complex electrification control, the press can arbitrarily program the stroke, speed, pressure, etc. of the slider, and can even reach the nominal tonnage of the press at low speed.

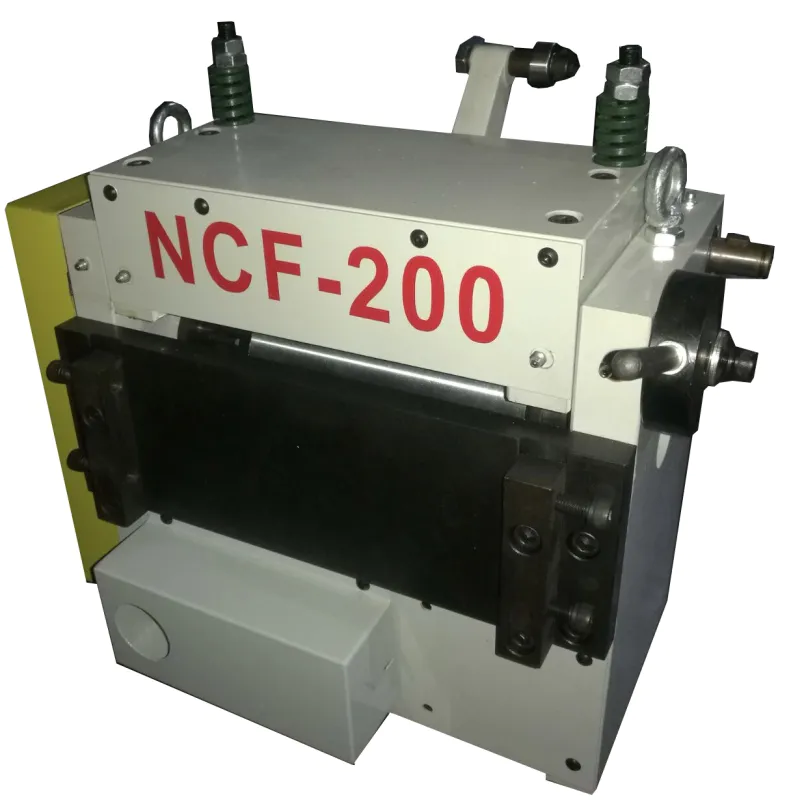

The press consists of a frame, a machine head, a worktable, a push rod, a platen, a motor, a motor controller, a reduction drive, a brake, a position sensor, a programmable controller, a touch screen, a working mechanism, and an auxiliary mechanism.

The press is mainly composed of a ball screw, a slider, a pressing shaft, a casing, a force sensor, a toothed synchronous transmission device, and a motor.

1. The motor is the driving device of the entire press. The analytical encoder of the motor can generate digital signals with a resolution of up to 0.1 microns, high precision, and fast measurement speed, which is suitable for large axial speeds.

2. The force sensor realizes the measurement of resistance through static elastic deformation, and has the advantages of good stability, low cost, wide application range and simple operation.

3. Ball screw and tooth-shaped synchronous transmission are all used to complete the transmission from the motor to the pressing shaft, which are characterized by stable structure, high precision and low failure rate.

The structure of the press is mainly composed of the main drive, the actuator and the auxiliary mechanism.

1. The main function of the main transmission mechanism of the press is to transmit the energy required for forging from the motor to the actuator. The common transmission methods include gear transmission, belt transmission, screw transmission and hydraulic transmission.

2. The main function of the actuator is to drive the slider to reciprocate and complete the forging process. Common actuators include crank-slider mechanism and crank wedge mechanism.

3. The main function of the auxiliary mechanism is to improve the reliability of the AC press, expand the technological use of the press, etc. Common auxiliary mechanisms include balance cylinder, brake, ejector device, position detection device, etc.