jackow@pressmachine-world.com+86-13817590728 WORLD power press machine manufacturer and supplier

Metal Stamping in the Automotive Industry

The automotive sector is a potent benchmark for a nation's degree of economic growth, which is why cars are dubbed "machines that change the world" for this reason. Stamping is the first and most important of the four main operations that go into making an automobile. The process of stamping in automotive industry involves using a press and metal stamping machine to apply an external force to a plate, strip, pipe, or profile. This force causes plastic deformation or separation, and the end product is a workpiece with the required size and shape.

In the plastics processing industry, stamping is a subset of forging. Stamping transforms 60–70% of the world's steel supply into finished goods, with hot-rolled and cold-rolled steel plates and strips being the primary materials used.

Automotive sheet metal stamping for automobiles uses metals, including steel, aluminum, and brass, as needed for each component. Steel is a popular material for structural components due to its strength and longevity. Vehicles benefit from aluminum's contribution to fuel economy due to its lightweight nature. Both the structural integrity and the visual attractiveness of the vehicle are enhanced by this approach. Because stamping can generate such complicated forms and patterns, producers may make designs that are both aerodynamic and aesthetically pleasing.

Advancements in Metal Stamping for Use in Automobile Parts

The efficacy and efficiency of metal stamping operations have been enhanced by the advent of newer, more technologically sophisticated stamping methods. Hybrid electromagnetically assisted sheet metal stamping tools are one example of an advanced metal stamping in automotive industry method that may change strain distribution and increase formability.

Automotive sheet metal stamping can manufacture components with pinpoint accuracy and minute tolerances because of the industry's dedication to investing in cutting-edge technology and the ongoing development of metal stamping processes. Copper, stainless steel, carbon steel, and exotic alloys are just a few of the metals that may be effectively pressed and shaped into vehicle components using today's metal stamping technologies.

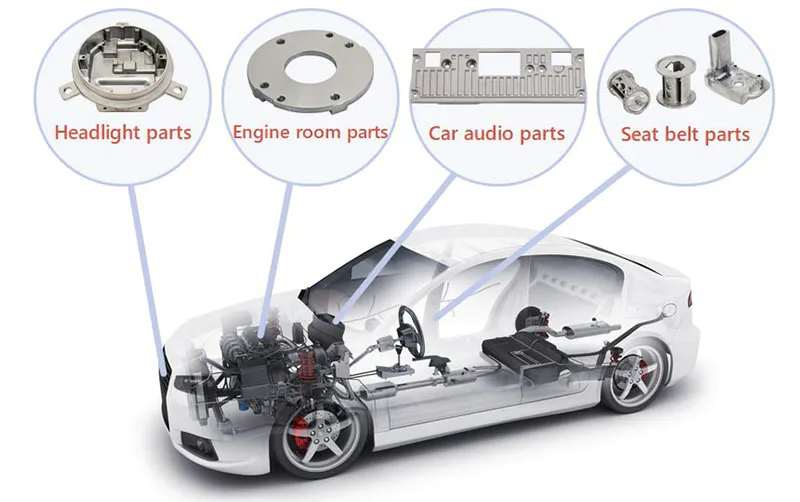

Stamped Metal Applications

Numerous goods and services are part of the automobile industry. The automotive industry relies on various components, but there is also a sizable and expanding aftermarket for specialized parts. Customers are able to personalize their vehicles to suit their demands by using aftermarket components and parts.

Crucial components, whether they are OEM or aftermarket, must frequently adhere to stringent industry requirements to guarantee dependability and safety. Fabricators engage in metal stamping for automotive applications when they are tasked with producing precise components that adhere to stringent specifications and exhibit very tight tolerances. To produce components and products that live up to these high expectations, metal fabricators in this field use a wide range of fabrication processes and technologies.

Metal stamping procedures are a really cheap way to make personalized car components, and they're employed to make a lot of important parts. Parts for vehicles that are metal stamped include:

● Horn buttons

● Fuel Injectors

● Steering wheel components and brakes

● Floor mat securement brackets

● Seat Latches

● Rearview mirror mounting plates

● Fuel Pressure Regulators

The Use of Hot Stamping in Automotive Industry

The car business has never been the same since the hot stamping automotive industry was introduced. The metal is heated until it becomes pliable and then stamped into form. The metal is cooled rapidly after formation to increase its strength. Critical to a vehicle's security, high-strength components, including door beams, bumpers, and pillars, are best produced using this method. In keeping with the industry's shift towards sustainability, hot stamping in automotive industry makes it possible to create components that are both lighter and stronger, which helps with fuel economy and emissions reduction.

Metal Stamping Growth and Spike

We anticipate more expansion and growth in the metal stamping market for automobile use in future years. According to industry predictions, metal-stamped car components are expected to reach approximately $300 billion in global demand by 2025.

Technological improvements in metal stamping techniques have contributed to this phenomenal growth rate. These methods are used by various sectors, including industrial equipment, consumer appliances, aircraft, automobiles, and more. Metal stamping in automotive industry is booming thanks to the increased demand for metal components caused by these sectors' expansion and development. Automobile manufacturers are able to keep customer prices down while yet meeting safety regulations because of the strength and flexibility of metal stamping components.

There are a number of things that will cause the metal stamping sector to develop at an exponential rate. A low-cost manufacturing technique that eliminates raw material waste is metal stamping. Using sheet metal in metal stamping for automotive applications boosts the production of chassis, transmission components, and structural parts for the inside and outside of vehicles.

As a flexible, trustworthy, and cost-effective manufacturing process, metal stamping is predicted to play an increasingly important role in producing engine and essential component metal alloys, including titanium, cast aluminium, cast iron, and forged steel. Metal-stamped automobile components are now of higher quality thanks to technological developments such as hybrid electromagnetically assisted sheet metal stamping machines.

Learn more about stamping in automotive industry and the machinery required from it at Yingxin.

Quick Links

Contact Us

• Tel: 86-21-62828320

• Fax: 86-21-62829970

• E-mail: jackow@pressmachine-world.com

• WHATSAPP: +8613817590728

• WEHCHAT: W13817590728

Add

• Exporting Office: 12F, Huaihai Road West, Shanghai, China

• Factory: Picheng World Industrial Park, Danyang City, Jiangsu Province, China