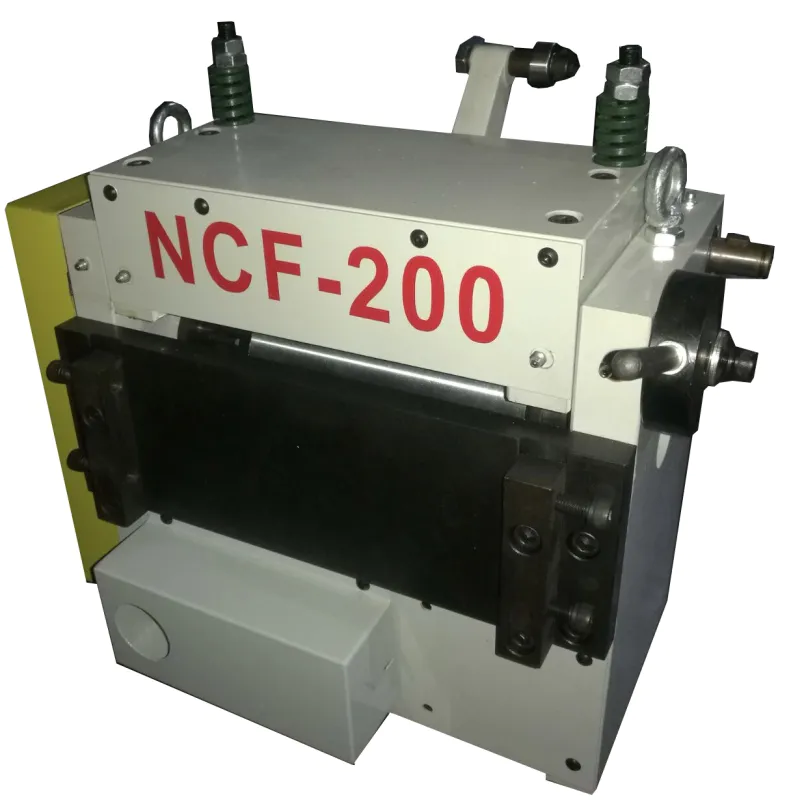

Press--Special press for bushing

As a new technology, WORLD Press Machine has the advantages that traditional hydraulic presses do not have. In the process of wheel bearing pressing and other processes, traditional hydraulic presses are gradually being replaced by means of equipment renewal, which effectively improves the level of automobile manufacturing technology.

Bushings are accessories that are used outside of mechanical parts to achieve sealing, wear protection, etc., and refer to the ring sleeve that acts as a gasket. In general, the bushing and the seat use an interference fit, and the shaft uses a clearance fit. In the past, the press-fitting bushings were mostly assembled by manually hitting the mandrel with a hammer or press-fitting by a hydraulic press. The installation phase and installation depth of the bushing lacked limit devices, and the press-fitting force could not be controlled, so the installation accuracy was difficult to guarantee. ; Due to the low installation accuracy, many unqualified bushings need to be reworked. When these bushings are taken out from the parts with special tooling, they will be scrapped and cannot be used again. The entire installation process is time-consuming and labor-intensive, and the installation efficiency is low. .

The WORLD Press Machine press is driven by an AC motor, outputs the force through a high-precision ball screw, and has a built-in high-precision pressure sensor and encoder, which can accurately measure parameters such as speed, pressure, and position. The software is used to precisely control the press-fitting pressure, stop position, press-fitting speed, and holding time in the whole process to realize the whole-process intelligent control and management.

In order to solve the above problems, WORLD Press Machine provides a press and press-fitting bushing assembly equipment solution, which can use a visual inspection and adjustment mechanism to ensure the angular position of the bushing, and use a press to press the bushing. The press-fitting position of the bushing is controlled by the press and the pressing-fitting quality is detected, which is efficient in operation and high in accuracy.

Main features:

1. A variety of press-fitting modes meet the requirements of high-precision and precise production and quality control.

2. Online press-fitting quality inspection meets the quality control and data management of the whole process of press-fitting.

3. The automatic compensation accuracy meets the precise assembly requirements under specific working conditions.

4. Environmental protection, energy saving and safety.

5. The self-diagnosis function meets the user's intelligent maintenance requirements.

Production process monitoring: pressure-displacement standard reference curve and upper and lower limit tolerance judgment window monitoring. It can be monitored online or offline.

With technology speeding up in lighting speed, have created quite a name for itself amidst automatic power press machine and it happens to have a lot of benefits as well.

The expert engineers of Shanghai Yingxin World Machinery Co., Ltd. always develop with utmost precision so that all quality standards are met during the production. we are looking forward to becoming a trusted supplier of customers. visit us at World Press Machine.

People are more likely to listen to an expert than just anyone off the street. So, while pack mentality is important, having a relevant expert speak to the effectiveness of a brand's product as WORLD is essential to converting new consumers as well.

The group's Quality Systems Manager (QSM) is responsible for ensuring that Shanghai Yingxin World Machinery Co., Ltd. has in place systems that guarantee quality throughout the Group.