jackow@pressmachine-world.com+86-13817590728 WORLD power press machine manufacturer and supplier

WORLD hot-sale 4 roll bending machine factory from best fatcory

| Items | unit | 63/2500 | 63/3200 | 100/2500 | 100/3200 | 100/4000 | 125/2500 | 125/3200 | 125/4000 | 160/2500 | 160/3200 | 160/4000 |

| Nominal pressure | kN | 630 | 630 | 1000 | 1000 | 1000 | 1250 | 1250 | 1250 | 1600 | 1600 | 1600 |

| Length of table | mm | 2500 | 3200 | 2500 | 3200 | 4000 | 2500 | 3200 | 4000 | 2500 | 3200 | 4000 |

| Distance between uprights | mm | 2050 | 2600 | 2050 | 2600 | 3300 | 2050 | 2600 | 3200 | 2050 | 2600 | 3400 |

| Throat depth | mm | 250 | 250 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 |

| Ram stroke | mm | 100 | 100 | 150 | 150 | 150 | 150 | 150 | 150 | 200 | 200 | 200 |

| Max. open height between ram and table | mm | 345 | 345 | 415 | 415 | 415 | 415 | 415 | 415 | 470 | 470 | 470 |

| Adjustment of Ram stroke | mm | 75 | 75 | 120 | 120 | 120 | 120 | 120 | 120 | 160 | 160 | 160 |

| Approach speed | mm/s | 90 | 90 | 120 | 120 | 120 | 110 | 110 | 110 | 100 | 100 | 100 |

| Bend speed | mm/s | 8 | 8 | 13 | 13 | 13 | 10 | 10 | 10 | 9.5 | 9.5 | 9.5 |

| Return speed | mm/s | 66 | 66 | 115 | 115 | 115 | 100 | 100 | 100 | 95 | 95 | 95 |

| Main motor | kW | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 11 | 11 | 11 | 11 | 11 | 11 |

| Overall dimension ( LxWxH ) | mm | 2560 | 3260 | 2650 | 3350 | 4150 | 2650 | 3350 | 4150 | 2560 | 3260 | 4060 |

| 1725 | 1725 | 1785 | 1785 | 1785 | 1785 | 1785 | 1785 | 1940 | 1940 | 1940 | ||

| 2280 | 2280 | 2460 | 2510 | 2560 | 2540 | 2560 | 2610 | 2660 | 2660 | 2660 | ||

| Weight | kg | 4400 | 5200 | 6100 | 7000 | 79000 | 6600 | 7300 | 8800 | 9000 | 9600 | 11800 |

(WC67Y) specification

Features:

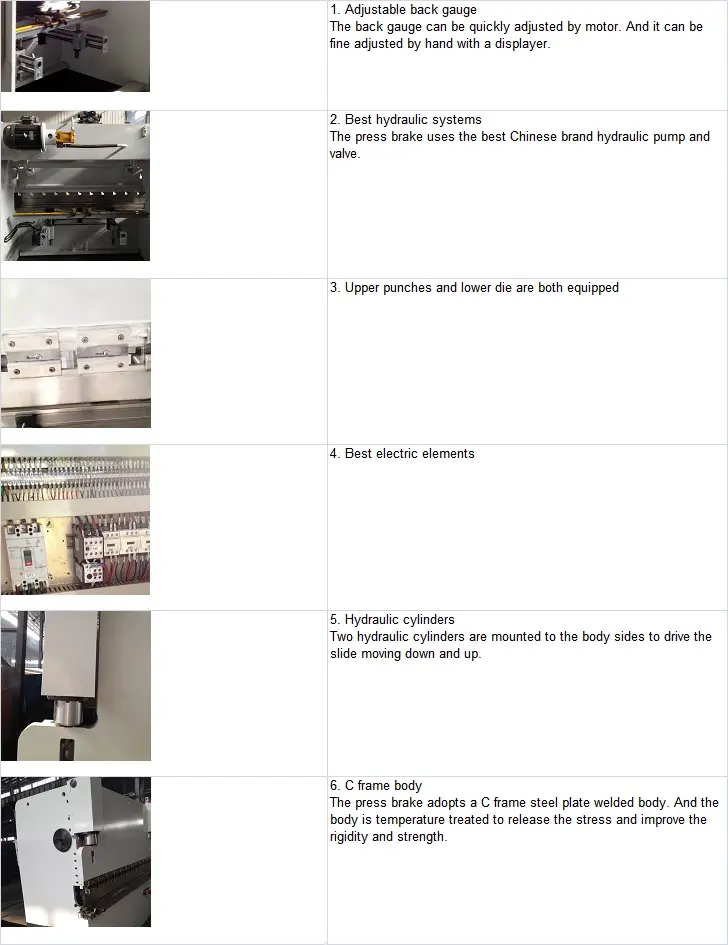

1. A fully welded steel construction with full strength and rigidity.

2. Hydraulic down-stroke construction.

3. Synchronizing mechanism of the ram adopting torque-tube and mechanical stop unit, stable and reliable.

4. Deflection-compensating mechanism of wedge construction.

5. Power fast adjustment, manual fine adjustment and counter-showing for the ram stroke.

6. Front-controlled backgauge by power fast-adjustment and manual fine-adjustment with counter display.

Quick Links

Contact Us

• Tel: 86-21-62828320

• Fax: 86-21-62829970

• E-mail: jackow@pressmachine-world.com

• WHATSAPP: +8613817590728

• WEHCHAT: W13817590728

Add

• Exporting Office: 12F, Huaihai Road West, Shanghai, China

• Factory: Picheng World Industrial Park, Danyang City, Jiangsu Province, China