jackow@pressmachine-world.com+86-13817590728 WORLD Power Press Machine Manufacturer And Supplier

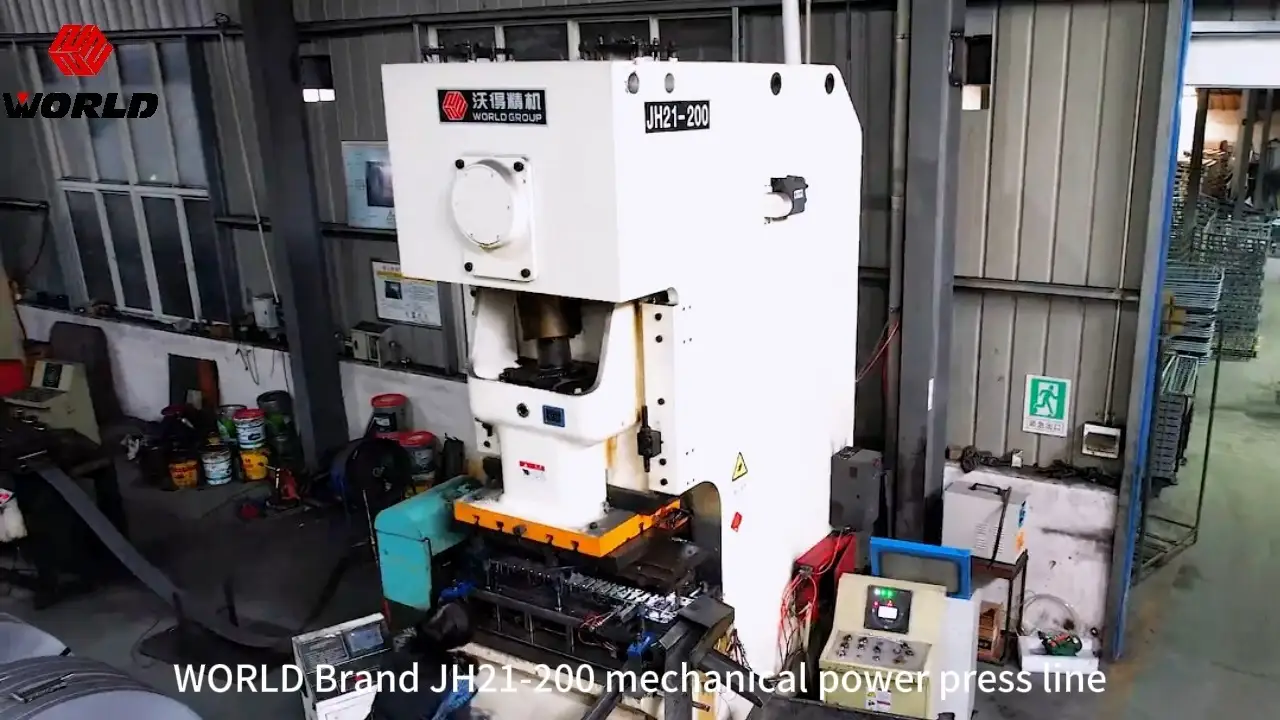

China Press machine - JH21-200 Ton Punching Press Machine

Features of 200 ton pneumatic press:

-Rectangular long sliding guide rails with high precision

-Inch, single stroke and continuous working modes can be switched

-Gap frame steel plate welded body

-Cross-arranged crankshafts with large gear transmission

-Wet pneumatic clutch and brake with double safety solenoid valves

-PLC control, HMI with monitoring function

-Electrically adjustable stamping height

JH21-200 Ton Punching Press Machine

200 Ton C Frame Punching Press Machine is an efficient industrial equipment designed for stamping, forming and punching small and medium-sized sheet metal parts. Its C-shaped open frame design is compact, providing excellent operating visibility and spatial adaptability, suitable for precision processing scenarios such as automotive parts, home appliance housings, metal brackets, etc.

200 Ton C Frame Punching Press Machine adopts a rigid reinforcement design: an integrated C-shaped steel plate welded body, optimized throat depth, strong anti-eccentric load capacity, and ensures stability under high tonnage.

200 Ton C Frame Punching Press Machine can be driven by hydraulic or mechanical options, supports single punching, continuous mode and automated integration, and is suitable for fast mold changeover of multi-station molds.

200 Ton C Frame Punching Press Machine has a small footprint and low energy consumption, making it an ideal choice for small and medium-sized processing plants and workshops to upgrade productivity.

How to operate the press correctly?

Start the main motor, and the indicator light on the panel will light up. Use the switch to select the working mode: inching, single, continuous. Adjust the air pressure to 0.5Mpa. Turn on the light safety gate switch.

Inching mode: turn the switch to non-continuous. Press the two-hand button and the press will start. Press once, the button will incline. Keep pressing the button and the button will complete a full stroke.

Single mode: Make sure the press rod stops at the top dead center (the crankshaft clock or light clock is at 12 o'clock). The operator can operate the press with the two-hand button or the foot pedal. There is a switch on the panel to select foot control or hand control.

Continuous: First turn the switch to continuous. Keep pressing the two-hand button until the crankshaft clock light passes 135 degrees (2-3 seconds). The press starts to run automatically and continuously. Press the emergency stop button or the continuous stop button to stop the press. Slider adjustment: Inch the press rod 360 degrees or 180 degrees (the connecting rod is vertical). Turn the slider adjustment switch to up or down, press the slider adjustment button, the ball screw works, and the slider rises or falls step by step. The above method can also be used for C-type power presses, connecting rod transmission power presses, industrial power presses, etc.

Quick Links

Contact Us

• Tel: 86-21-62828320

• Fax: 86-21-62829970

• E-mail: jackow@pressmachine-world.com

• WHATSAPP: +8613817590728

• WEHCHAT: W13817590728

Add

• Exporting Office: 12F, Huaihai Road West, Shanghai, China

• Factory: Picheng World Industrial Park, Danyang City, Jiangsu Province, China