jackow@pressmachine-world.com+86-13817590728 WORLD power press machine manufacturer and supplier

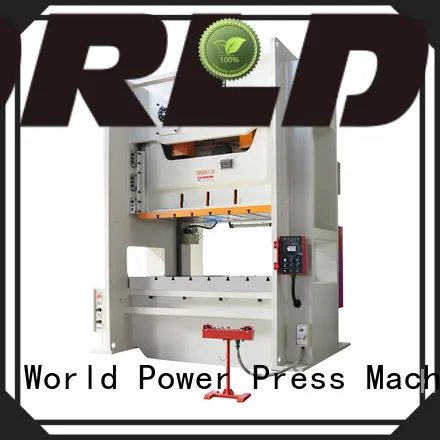

WORLD mechanical press for sale at discount

Product Details

With the dedication to pursue excellence, Yingxin strives for perfection in every detail.Power Press Machine Manufacturers is in line with the stringent quality standards. The price is more favorable than other products in the industry and the cost performance is relatively high.

1. WORLD mechanical press for sale is produced under the standardized and scientific production process. The production of the product is constantly monitored for 24 hours.

2. The product has been tested by many quality norms and has been approved to be qualified in all respects, such as performance, service life, and so on.

3. Shanghai Yingxin World Machinery Co., Ltd. has been widely recognized by domestic and international customers.

4. World Power Press Machine has extensive reputation and popularity.

Company Features

1. As a professional manufacturer of mechanical press machine , Shanghai Yingxin World Machinery Co., Ltd. insists on high quality.

2. Carrying out the most advanced technical methods better guarantees the quality of mechanical press .

3. Shanghai Yingxin World Machinery Co., Ltd. is successful through continuous efforts to provide greater value to customers. Get an offer! Shanghai Yingxin World Machinery Co., Ltd. will pursue more stable endlessly stamping press . Get an offer!

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

Quick Links

Contact Us

• Tel: 86-21-62828320

• Fax: 86-21-62829970

• E-mail: jackow@pressmachine-world.com

• WHATSAPP: +8613817590728

• WEHCHAT: W13817590728

Add

• Exporting Office: 12F, Huaihai Road West, Shanghai, China

• Factory: Picheng World Industrial Park, Danyang City, Jiangsu Province, China