jackow@pressmachine-world.com+86-13817590728 WORLD power press machine manufacturer and supplier

hot-sale power press machine manufacturers for die stamping

Place of Origin:

Jiangsu China

Payment:

L/C, T/T

MOQ:

1

Model:

JW31-160

Brand:

WORLD

Supply Ability

2000 Unit/Units per Year

Start Port

Shanghai China

Material

Metal

Delivery Time

45 days

Certification

CE, CCC

Availability

OEM

Company Advantages

1. The freezing technology of WORLD has been significantly improved to reduce the harmful impacts of chemical refrigerants on the environment. It has advantages in internal mechanical performance, such as smooth operation

2. 'Provide quality services for customers' is the tenet of World Power Press Machine. With a quality servo motor, it is highly efficient

3. Its quality will be checked out with 100% attention by our QC team. The product will stop immediately once it is overload than 110% to protect both the press and the die

Company Features

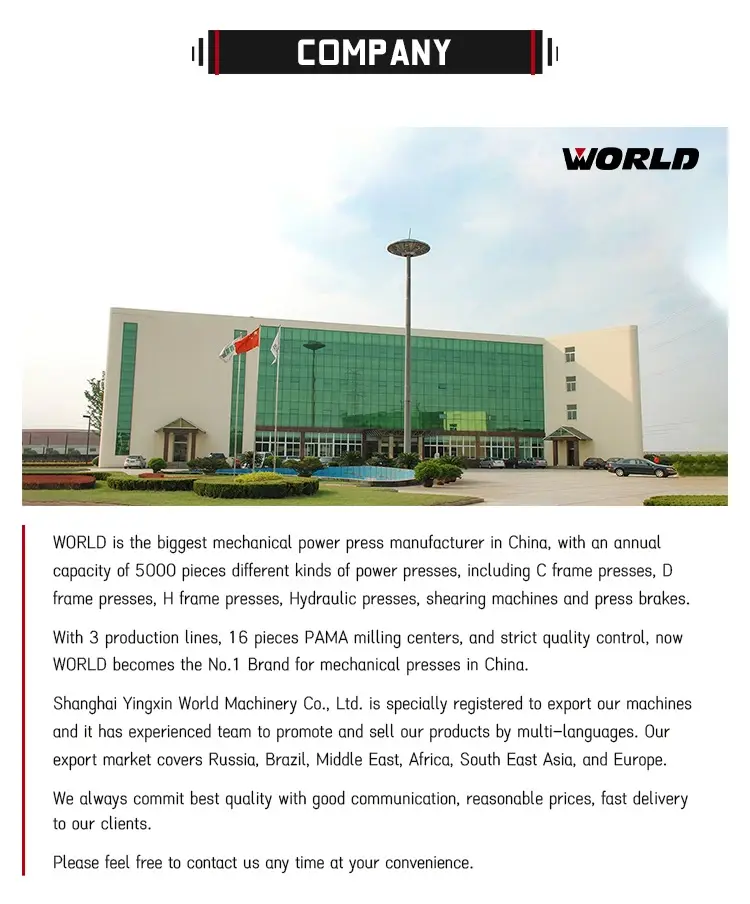

1. power press machine is processed by experienced technicians of WORLD.

2. In order to satisfy ever-changing market demands, we always devoted ourselves to developing new products and striving for innovative R&D. Our goal is to provide the most stable quality products and quick services for customers.

1. The freezing technology of WORLD has been significantly improved to reduce the harmful impacts of chemical refrigerants on the environment. It has advantages in internal mechanical performance, such as smooth operation

2. 'Provide quality services for customers' is the tenet of World Power Press Machine. With a quality servo motor, it is highly efficient

3. Its quality will be checked out with 100% attention by our QC team. The product will stop immediately once it is overload than 110% to protect both the press and the die

Company Features

1. power press machine is processed by experienced technicians of WORLD.

2. In order to satisfy ever-changing market demands, we always devoted ourselves to developing new products and striving for innovative R&D. Our goal is to provide the most stable quality products and quick services for customers.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

Quick Links

Contact Us

• Tel: 86-21-62828320

• Fax: 86-21-62829970

• E-mail: jackow@pressmachine-world.com

• WHATSAPP: +8613817590728

• WEHCHAT: W13817590728

Add

• Exporting Office: 12F, Huaihai Road West, Shanghai, China

• Factory: Picheng World Industrial Park, Danyang City, Jiangsu Province, China